In modern home design, the choice of a sofa is no longer limited to its appearance and comfort; the personalization and functionality of materials are becoming a new trend. Customized PVC synthetic leather for sofa is gaining popularity among home and commercial space designers due to its unique advantages. Compared to traditional fabrics or genuine leather, PVC synthetic leather not only offers a rich variety of colors and textures but also meets a wide range of demanding functional requirements, such as flame retardancy, water resistance, and abrasion resistance, providing consumers with unprecedented freedom and practicality. Its emergence has not only transformed how sofas are made but also allows more people to realize their aspirations for high-quality home furnishings at a more reasonable cost.

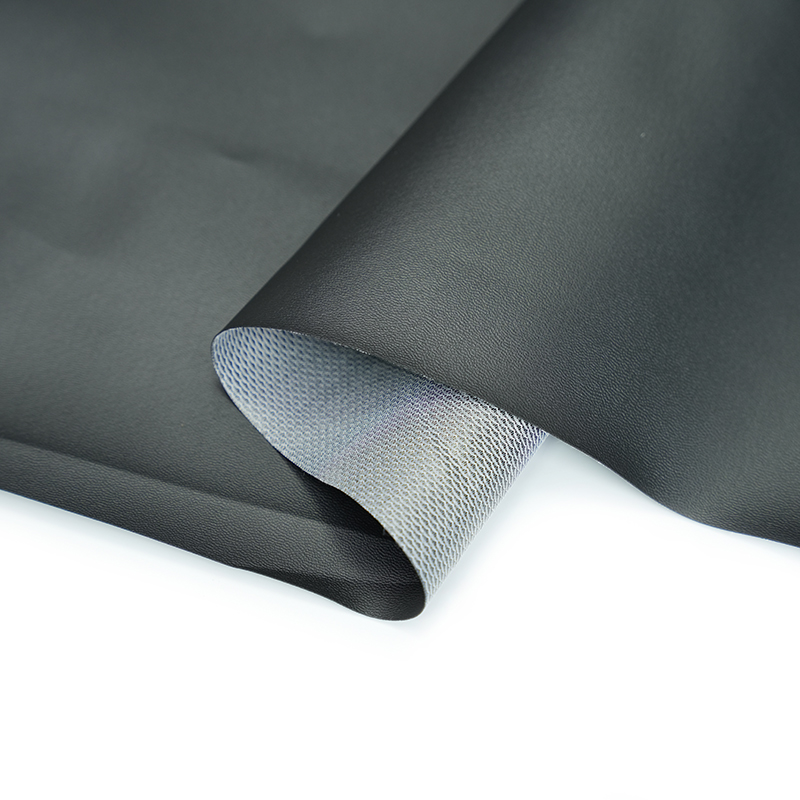

To deeply understand the value of customized PVC synthetic leather, one must first explore the precise manufacturing process behind it. The production of PVC synthetic leather typically involves several stages: base fabric preparation, coating, foaming, embossing, and post-processing. First, a high-strength, stretch-resistant base fabric, such as knitted or non-woven fabric, is selected as the support layer. Then, a liquid polyvinyl chloride (PVC) mixture is uniformly coated onto the base fabric. During the coating process, specific additives like plasticizers, stabilizers, and foaming agents can be included in the formula to give the material different physical properties. For example, by adding a flame retardant, it's possible to produce flame-retardant sofa leather that meets international safety standards, effectively reducing the risk of fire. Furthermore, special surface treatments can achieve water-resistant, stain-proof, and antibacterial functions, making the sofa easier to clean and maintain in daily use. Finally, high-temperature embossing can be used to simulate various natural textures, such as the litchi or crocodile grain of genuine leather, or unique geometric patterns, offering designers infinite creative possibilities.

Choosing a customized PVC synthetic leather for sofa is more than just picking an off-the-shelf product; it's a deep collaborative process from concept to reality. This process typically begins with the customer outlining their specific requirements, including color, texture, feel, thickness, and special functional needs. A qualified supplier will communicate in detail with the customer and provide various existing samples for reference. Once the customer has determined the basic direction, the supplier will create a small-batch sample based on the customer's unique requirements. This sample is a crucial part of the entire customization process because it must not only accurately reflect the customer's design intent but also undergo a series of rigorous performance tests to ensure all indicators meet the standards. Only after the sample receives final confirmation from the customer can large-scale production begin. During production, quality control is paramount. Each batch of raw materials is inspected, and the final products undergo strict physical performance tests for things like abrasion resistance, colorfastness, and tensile strength, ensuring every roll of synthetic leather meets high-quality standards. Finally, after production and inspection are complete, the products are delivered to the customer at the agreed-upon time and in the agreed-upon manner, bringing the entire customization process to a successful conclusion.

Compared to natural genuine leather, customized PVC synthetic leather has a significant cost advantage, providing a similar visual and tactile experience at a lower price. At the same time, the environmental friendliness of PVC synthetic leather has been greatly improved with modern production techniques; many products use solvent-free technology and do not involve animal hides, which is more in line with the concept of sustainable development. In terms of maintenance, PVC synthetic leather is easy to clean and stain-resistant, requiring only a wipe with a damp cloth, while genuine leather needs professional care. Compared to PU leather and microfiber leather, PVC synthetic leather is generally superior in hardness and abrasion resistance, making it particularly suitable for high-traffic public spaces like restaurants, hotels, and offices. While PU and microfiber leather may be closer to genuine leather in terms of breathability and softness, PVC synthetic leather offers a higher cost-performance ratio in terms of price and durability.

Looking ahead, the development of customized PVC synthetic leather will focus more on intelligence and functionality. For example, some advanced manufacturers are developing PVC leather with self-healing coatings or integrated smart temperature control features, turning the sofa from mere furniture into a smart home device. As consumer demand for personalization and eco-friendliness continues to grow, customized production will become the mainstream, and the collaboration between suppliers and designers will become closer. Through continuous technological innovation and material upgrades, PVC synthetic leather will continue to expand its application areas, providing high-performance, high-value material solutions for more industries, including home furnishings, automotive, and medical fields. This is not only a challenge to traditional materials but also a proactive exploration of future lifestyles.