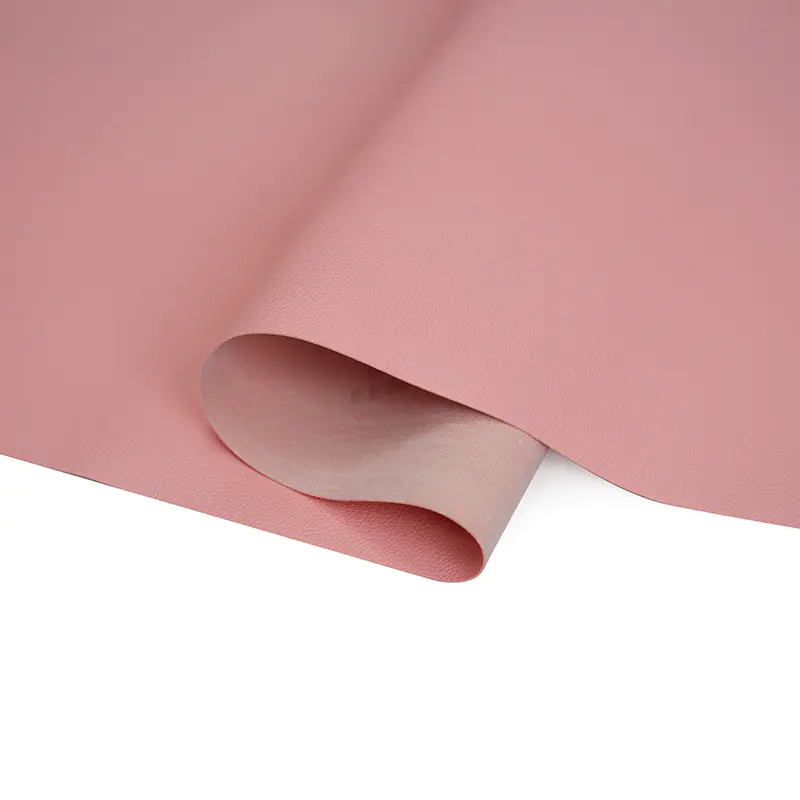

In the field of modern furniture decoration, PVC artificial leather for sofas has become a widely used material due to its unique combination of properties. Its core advantage lies in the balance between cost-effectiveness and functionality: compared with natural leather, PVC artificial leather costs only one-third to half the price, yet can mimic similar textures and feel, while boasting superior waterproof performance. The polyvinyl chloride coating on its surface can completely block liquid penetration, making it easy to wipe clean even if beverages are spilled. This material’s structural characteristics give it excellent tensile resistance—high-quality PVC artificial leather can maintain structural integrity even under 10% tensile deformation, rarely developing cracks, which makes it suitable for furniture like sofas that need to withstand long-term sitting pressure.

Furthermore, PVC artificial leather offers exceptional plasticity in terms of colors and textures, capable of replicating effects like imitation cowhide or sheepskin. Its color uniformity is high, without the natural flaws inherent in genuine leather. In terms of maintenance convenience, it doesn’t require regular application of maintenance oil like real leather; daily cleaning only requires wiping with a damp cloth, making it particularly suitable for families with children or pets. These characteristics allow PVC artificial leather to balance aesthetics and practicality while reducing the cost of using and maintaining furniture, thus becoming one of the mainstream choices for sofa fabrics.

The stain resistance of PVC artificial leather for sofas directly affects the durability of its appearance, requiring scientific testing and proper maintenance methods. Stain resistance testing can adopt methods that simulate daily stains: dripping common contaminants such as soy sauce, coffee, and edible oil on the surface of PVC artificial leather, allowing them to sit for 30 minutes, then wiping with clean water or neutral detergent to observe if any traces remain. High-quality products should be able to completely remove stains without pigment residue; obvious marks indicate insufficient surface coating density and poor stain resistance.

Daily maintenance requires careful selection of cleaning methods: for dry stains like dust, use a soft brush to sweep gently before wiping with a slightly damp cloth; for oil stains or beverage spills, handle them promptly after contamination—first absorb the liquid with paper towels, then gently wipe with a cloth dipped in diluted neutral detergent (such as a 1:10 mixture of dish soap and water), and finally wipe off residual detergent with a clean water cloth. Avoid using organic solvents like alcohol or gasoline, as they may damage the surface coating.

Additionally, a deep cleaning with special PVC cleaner can be performed monthly to remove stubborn stains while replenishing coating oils to maintain fabric softness. However, care should be taken not to use excessive amounts to prevent greasy residues on the surface. During long-term use, avoid scratching the surface with sharp objects and keep it away from heat sources like heating vents or air conditioning outlets to prevent high temperatures from causing the fabric to harden and crack, which would affect stain resistance.

Dark-colored PVC artificial leather sofas are prone to fading during long-term use, mainly due to material properties and usage environment. From a material perspective, colorants in dark PVC artificial leather (especially dark pigments like black and dark brown) are prone to oxidative decomposition under ultraviolet radiation, leading to lightening of color;Uneven mixing of pigments with PVC resin during production can cause local faster fading.

In terms of usage environment, direct sunlight is the primary inducement—sofas on balconies or near windows that receive more than 3 hours of direct sunlight daily may show obvious fading within 6-12 months. Furthermore, high-temperature environments (such as near heating appliances) accelerate molecular movement, reducing pigment stability, while humid environments may cause slight dissolution of the surface coating, indirectly triggering fading.

Preventing fading requires multiple approaches: first, reduce ultraviolet exposure by installing sunshades or applying anti-ultraviolet films on windows to reduce direct sunlight intensity, or regularly adjusting the sofa position to avoid long-term exposure of fixed areas. Second, choose PVC artificial leather products containing ultraviolet absorbers, which can absorb ultraviolet rays with wavelengths of 300-400nm, reducing pigment oxidation. During daily cleaning, avoid using detergents containing bleaching ingredients, as such substances will damage the pigment structure. For areas with slight fading, special PVC repair agents (matching the color number) can be gently applied to form a protective film while replenishing color, slowing down the overall fading rate.

The durability differences between PVC artificial leather sofas and fabric sofas are mainly reflected in wear resistance, stain resistance, and service life, requiring selection based on usage scenarios. In terms of wear resistance, the plastic coating on the surface of PVC artificial leather has excellent wear resistance—tests show it can withstand more than 50,000 wear cycles (tested with a standard abrasion tester), while ordinary fabric sofa fabrics (such as cotton and linen) typically withstand 20,000-30,000 cycles. With frequent use, artificial leather sofas are less likely to experience pilling or fiber breakage.

In terms of stain resistance, the waterproof and oil-resistant properties of PVC artificial leather make it more resistant to liquid stains, while fabric sofa fabrics are mostly porous, allowing liquids to penetrate into fibers, making thorough cleaning difficult and prone to mold growth over time. In terms of service life, PVC artificial leather sofas can last 5-8 years with proper maintenance, but may shorten to 3-5 years in high-temperature and dry environments. Fabric sofas usually have a service life of 3-5 years; although the fabric can be removed and washed, frequent washing reduces fiber strength, and the frame support may also be damaged by moisture.

However, fabric sofas have an advantage in breathability, being less likely to cause stuffiness during long periods of sitting or lying, while PVC artificial leather has poor breathability and may require breathable cushions in summer. Overall, PVC artificial leather sofas are more suitable for families pursuing durability and easy maintenance, while fabric sofas are ideal for users valuing comfort and style changes.

In low-temperature environments (such as unheated rooms in winter or northern regions without heating), sofa PVC artificial leather tends to harden and lose elasticity, potentially leading to cracks, requiring targeted protective measures. In terms of material properties, PVC artificial leather gradually hardens below 10°C and significantly loses elasticity below 0°C; if stretched or squeezed under such conditions, surface cracks may appear.

The core of protection lies in maintaining material flexibility: first, control the ambient temperature by placing a small heater near the sofa (at least 50cm away) to maintain local temperature above 15°C, but avoid prolonged direct exposure to high temperatures. Second, regularly apply special PVC softener once a month—spray the softener evenly on the surface and wipe with a soft cloth; its ingredients can penetrate into the coating, preventing plastic molecules from hardening due to low-temperature crystallization.

In terms of usage habits, avoid pressing or pulling the sofa edges forcefully in low temperatures, rise slowly to reduce instantaneous stress; if the sofa is in a low-temperature environment for a long time, cover it with a sofa cover to keep warm and reduce temperature fluctuations’ impact on the material. For areas with tiny cracks, promptly fill them with PVC repair paste—first clean and dry the cracked area, then squeeze the repair paste into the gap, smooth with a scraper, and let it cure for 24 hours to prevent crack expansion while restoring some flexibility.

Seams of PVC artificial leather sofas are prone to delamination (separation of surface coating from the base layer) due to long-term stress and friction; timely repair can extend service life. Tools needed for repair include: special PVC adhesive, fine sandpaper, clean cloth, plastic scraper, and heavy objects (such as books).

First, handle the delaminated area: Gently sand the edges of the delaminated seam with fine sandpaper to remove lifted aging coating, taking care to use light force to avoid damaging the surrounding intact fabric; then wipe the sanded surface with a cloth dipped in alcohol to thoroughly remove dust and grease, ensuring the adhesive can effectively adhere.

Next, apply the adhesive: evenly spread special PVC adhesive on the delaminated base layer and the back of the fabric, with a thickness of about 0.1-0.2mm—avoid applying too thickly to prevent overflow; after application, let it sit for 5-10 minutes (adjust according to adhesive instructions) until the surface is slightly dry but still sticky, then align the fabric with the original position and press gently, use a plastic scraper to push from the center of the seam to both sides to expel air and excess adhesive, ensuring a tight fit.

Finally, fix the repair: wipe off the squeezed adhesive with a clean cloth, cover the repaired area with a layer of cotton cloth, place a heavy object (weighing about 2-3kg) to press it down, and let it cure completely for 24 hours, avoiding contact or use of the sofa during this period. After curing, check if the seam is flat; if there are still tiny bubbles, pierce them with a needle and press again. During daily use, avoid placing heavy objects or frequent friction at the seams, and place a thin cloth at the seam positions to reduce direct stress and prevent recurrence of delamination.