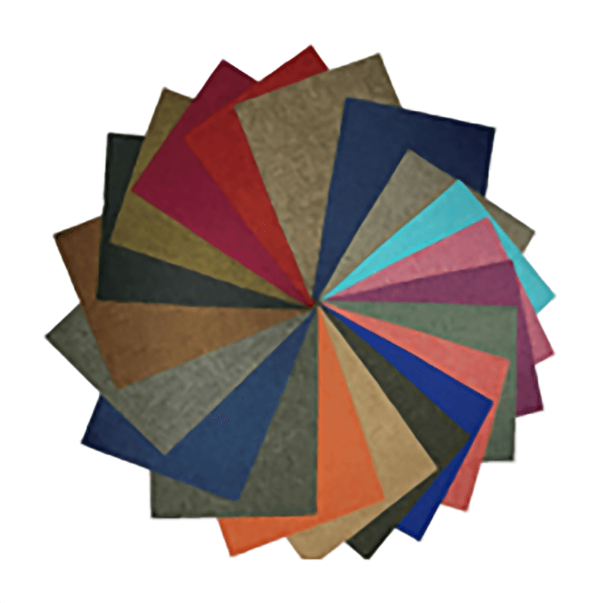

In the vast market of bag materials, Mosaic Oxford Fabric has steadily carved out its own niche, thanks to its unique visual charm and outstanding functionality. The core of its appeal lies in its exquisite mosaic pattern, an intricate design composed of geometric shapes that breaks away from the monotony of traditional solid-colored fabrics. This artistic touch infuses products with a vibrant energy and a sophisticated texture. Beyond simply catching the consumer’s eye, this pattern also cleverly conceals minor stains or scuffs, ensuring that bags maintain their pristine appearance for a longer period. Whether it’s used for crafting fashionable travel suitcases, casual backpacks, or practical storage bags, Mosaic Oxford Fabric elevates an ordinary everyday item into a piece of art that seamlessly blends utility with a sense of design. This perfect marriage of aesthetics and practicality is precisely why it has garnered such widespread admiration.

For any high-quality bag material, durability is an absolutely critical consideration. The exceptional sturdiness and longevity of Mosaic Oxford Fabric are rooted in its 600D high-density weaving process. Here, “D” stands for Denier, a unit used to measure the linear mass density of a fiber. A high density of 600D signifies that a greater number of yarns are woven into a given unit area, resulting in an exceptionally tight and dense structure. This compact weaving technique endows the fabric with excellent resistance to stretching and tearing. When a bag is carrying heavy items, the fabric won’t easily deform or rupture. In daily use, it can also effectively resist scuffs and scrapes from sharp objects, significantly extending the product’s lifespan. This relentless pursuit of durability ensures that Mosaic Oxford Fabric is more than just a decorative textile; it is a reliable material built to withstand the test of time.

In addition to its high-density woven structure, the powerful functionality of Mosaic Oxford Fabric is further enhanced by the PVC coating on its reverse side. This thick, robust coating acts like an impregnable shield, providing crucial protection for the fabric. First and foremost, it grants the fabric superior waterproof performance. When faced with sudden rain or accidental spills, water droplets bead up and roll off the coated surface, effectively protecting the contents of the bag from moisture damage. Secondly, the PVC coating significantly boosts the fabric’s abrasion resistance. During daily use, the bottom and edges of bags are often subjected to friction against the ground or walls. This tough coating effectively resists this continuous wear and tear, preventing fiber breakage and preserving the bag’s integrity and aesthetic appeal. This dual protection of waterproofing and abrasion resistance makes Mosaic Oxford Fabric an ideal choice for outdoor gear and travel luggage.

Mosaic Oxford Fabric typically has a thickness of 0.5mm, a seemingly minor detail that, in fact, embodies a great deal of design ingenuity. This specific thickness ensures the fabric is both sturdy and durable, capable of withstanding the rigors of daily use and heavy loads, while also maintaining a desirable level of flexibility and lightness. Fabric that is too thick would increase the bag’s weight, making it cumbersome and inconvenient to carry, while a material that is too thin would compromise its protective qualities. The 0.5mm thickness cleverly strikes a perfect balance between these two extremes. It allows bags to offer solid protection while remaining lightweight, ensuring consumers can enjoy its functionality without feeling burdened. This precise calibration of thickness reflects a deep consideration for the material’s practical applications.

Mosaic Oxford Fabric is typically produced with a 140cm width, a standard dimension that offers immense convenience for both manufacturers and designers. This wide format allows for the cutting of large bag components with minimal splicing, and in some cases, allows for a single, seamless cut. This not only simplifies the production process but also enhances the overall aesthetic quality of the final product. More importantly, a wider fabric width significantly improves material utilization, reducing waste from offcuts and thereby lowering production costs, a factor that is especially crucial for large-scale manufacturing. For designers, the 140cm width provides a broader canvas for creativity. They can freely plan the orientation of patterns and the structure of the bag without being constrained by size limitations, enabling the creation of more diverse and innovative products. This wide-format design undoubtedly opens up a wider range of possibilities for Mosaic Oxford Fabric in the bag market.