In the diverse landscape of textile manufacturing, the debate between synthetic and natural materials remains a pivotal topic for engineers and procurement professionals. PVC Artificial Leather, also known as polyvinyl chloride leather, has long been a staple in the industry due to its robust mechanical properties and cost-effectiveness. As B2B buyers seek to optimize the lifespan of products ranging from upholstery to automotive interiors, understanding the nuanced performance differences between PVC, Polyurethane (PU), and genuine leather is essential. This comparison is not merely about initial cost but involves a deep analysis of tensile strength, abrasion resistance, and environmental tolerance. With advancements in chemical engineering, modern synthetic leathers are increasingly bridging the gap with natural hides, offering specific durability advantages that are critical for high-traffic and heavy-wear applications.

Jiangyin Jiangdong Plastic Co., Ltd. has been at the forefront of this industry since its founding in 1999, dedicated to the development, production, and sale of high-quality PVC Artificial Leather. With a sprawling manufacturing area of 35,000 square meters, the company has integrated advanced production lines imported from Germany, Japan, and Taiwan, creating a seamless workflow encompassing weaving, dyeing, and film sticking. This state-of-the-art facility allows Jiangyin Jiangdong to apply cutting-edge technology in producing a vast array of products, including bag leather, shoe leather, sofa leather, decoration leather, car mats, and advertisement films. Achieving an annual output of more than 60 million meters, their products are primarily exported to Southeast Asia, the Middle East, South Africa, and other regions, serving a global clientele that demands consistent durability and performance.

The synthetic leather market is currently witnessing significant technological shifts aimed at improving product longevity and sustainability. According to the 2024 Market Analysis Report by Grand View Research, the global synthetic leather market size is expected to expand significantly, driven by advancements in bio-based polyols and improved surface treatment technologies that enhance abrasion resistance without compromising flexibility. This trend indicates that manufacturers are increasingly focusing on engineering materials that can withstand rigorous usage cycles while maintaining their aesthetic integrity, a factor that is becoming a decisive quality metric for industrial buyers.

Source: Grand View Research - Synthetic Leather Market Analysis

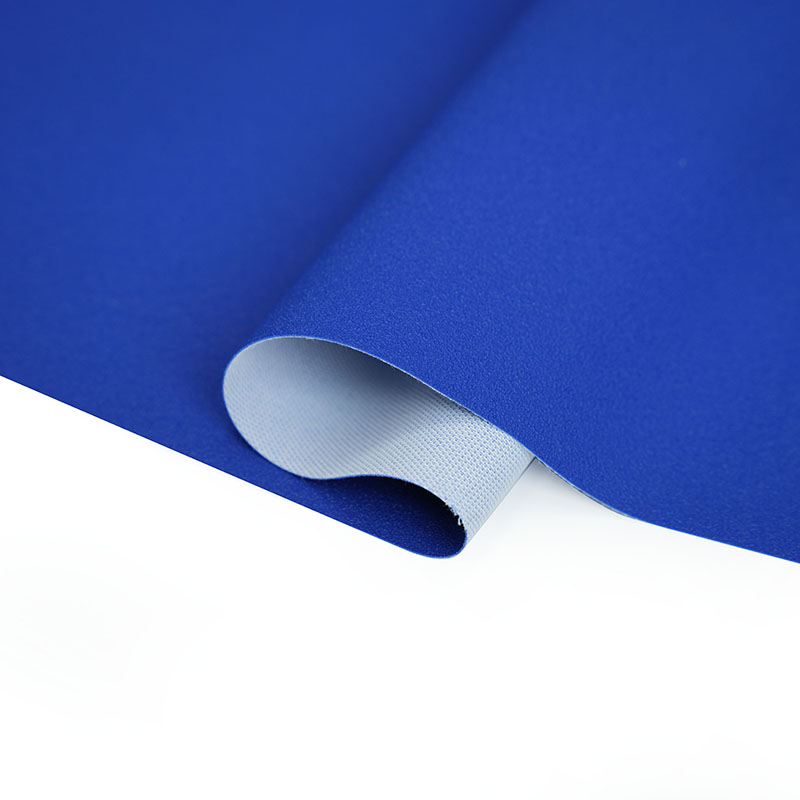

Understanding the durability of any material begins with its composition and structural architecture. PVC Artificial Leather is composed of a polyvinyl chloride resin paste applied to a backing fabric, which is often a knitted polyester or a non-woven substrate. This structure creates a bond where the chemical coating provides the surface resistance, while the backing contributes to tensile strength. In contrast, genuine leather possesses a complex, interlocking network of collagen fibers that provide natural breathability and strength. PU leather, on the other hand, utilizes a polymer layer that is more porous than PVC, adhering to a backing usually via a wet or dry coagulation process.

The method of production plays a critical role in the final durability of the material. For PVC Artificial Leather, the calendering process involves squeezing the PVC compound between rollers to form a film, which is then laminated onto the fabric. This results in a very consistent thickness and high surface density. Conversely, the coating process, often used for PU, involves spreading the chemical directly onto the fabric, which can penetrate the weave and create a stronger mechanical bond. When sourcing durable PVC leather fabric rolls, buyers should prioritize products that utilize high-temperature calendering, as this ensures the plasticizers are evenly distributed, preventing future brittleness.

td>Slower due to curing times for solvent evaporation. td>Slowest; involves multi-day tanning processes.

| Process Characteristic | PVC Artificial Leather (Calendered) | PU Leather (Coated) | Genuine Leather (Tanned) |

| Surface Uniformity | Highly uniform; thickness is easily controlled. | Generally uniform, but can vary with coating depth. | Natural variations; thickness varies across the hide. |

| Layer Adhesion | Adhesion via heat and pressure; susceptible to peeling if adhesive fails. | Chemical bond; often more flexible and resistant to peeling. | Integral fibers; no layer separation risk. |

| Production Speed | Fast; suitable for high-volume orders like durable PVC leather fabric rolls. |

When evaluating materials for high-traffic applications such as upholstery or footwear, abrasion resistance is a paramount concern. PVC Artificial Leather typically exhibits superior resistance to surface scuffs and scratches compared to PU and many types of genuine leather. This is due to the addition of plasticizers and the inherent hardness of the PVC polymer. While genuine leather is durable, it is susceptible to scratches that can cut into the fiber structure; however, it can often be buffed out. PU leather offers a softer hand feel but generally has lower abrasion resistance than PVC. In environments where surface wear is the primary failure mode, PVC Artificial Leather often outperforms its counterparts by maintaining its surface integrity over thousands of cycles.

The durability of PVC Artificial Leather is heavily reliant on plasticizers, chemical additives that impart flexibility. Without them, PVC would be rigid and prone to cracking. In applications involving frequent movement, such as seating or bags, the correct balance of plasticizer is crucial. PVC leather for furniture upholstery must withstand constant folding and stretching. If the formulation is too hard, the material will develop surface cracks; if too soft, the material may deform permanently. Modern manufacturing utilizes high-molecular-weight plasticizers that resist migration, ensuring that PVC leather for furniture upholstery remains supple and crack-free for years.

td>Risk increases with plasticizer loss due to heat or age.td>High resistance; color goes through the thickness.

| Failure Mode | PVC Artificial Leather | Genuine Leather |

| Cracking | Risk increases if the hide dries out and loses natural oils. | |

| Surface Abrion | Surface finish can wear away, revealing lighter underneath layers. | |

| Tearing | Depends on backing strength; generally good puncture resistance. | Very high tear resistance, especially in full-grain hides. |

One of the distinct advantages of synthetic materials over natural hides is their resistance to water and environmental factors. Waterproof PVC synthetic leather is virtually impermeable to liquids, making it an ideal choice for applications where spillage or moisture is a concern, such as outdoor furniture, bags, and automotive interiors. Genuine leather is hygroscopic, meaning it absorbs moisture, which can lead to swelling, staining, or mold growth if not treated correctly. PU leather offers moderate water resistance but can absorb water at the seams or through the micro-porous structure over time. For waterproof PVC synthetic leather, the non-porous nature of the material prevents staining and simplifies cleaning, a key selling point for hospitality and healthcare sectors.

When considering long-term durability, maintenance requirements must be factored into the total cost of ownership. Waterproof PVC synthetic leather is exceptionally easy to maintain; usually requiring only a damp cloth for cleaning. However, prolonged exposure to UV radiation can degrade the plasticizers, leading to fading and embrittlement. Eco-friendly PVC faux leather addresses this by using organic stabilizers that are less harmful to the environment and more effective at resisting UV degradation. In contrast, genuine leather requires regular conditioning to prevent drying out and cracking, which demands labor and materials over the product's life.

| Environmental Factor | PVC Artificial Leather | PU Leather | Genuine Leather |

| Water Resistance | Excellent; inherently waterproof. | Good; but can absorb water through seams or coatings. | Poor; requires protective treatments to repel water. |

| Stain Resistance | High; non-porous surface wipes clean. | Moderate; some stains may penetrate the polyurethane layer. | Variable; porous nature makes it susceptible to permanent staining. |

| UV Resistance | Moderate to High; depends on stabilizers used in eco-friendly PVC faux leather. | Moderate; prone to yellowing if not treated. | Low; fades and dries out unless constantly protected. |

Tensile strength and flexibility are critical metrics that determine how a material handles mechanical stress. PVC Artificial Leather generally possesses high tensile strength derived from its fabric backing, but its flexibility can vary based on the temperature and the formulation. Genuine leather is renowned for its flexibility, which improves with use as the fibers align, offering superior comfort. PU leather sits in the middle, offering better flexibility than PVC but lower tensile strength than heavy-duty PVC reinforced with strong backings. For specific applications requiring structural rigidity, such as 1.2mm PVC artificial leather, the thickness provides significant resistance to stretching and deformation, making it suitable for industrial covers or rigid bags.

Selecting the correct thickness is vital for ensuring durability. A standard 0.8mm thickness might be suitable for garments, but for heavy-duty applications, 1.2mm PVC artificial leather is often specified. This increased thickness adds mass and rigidity, contributing to a higher perceived quality and greater resistance to puncture and tearing. When comparing 1.2mm PVC artificial leather to a 1.2mm hide of genuine leather, the PVC will generally be stiffer but more uniform in density. The genuine leather of the same thickness will be more pliable but may have weak spots depending on the animal's origin.

td>Edges hold shape well; easier to finish. td>Edges are strong but may fray if not finished.

| Property | Thin PVC (0.6-0.8mm) | Thick PVC (1.2mm+) | Genuine Leather (1.2mm) |

| Flexibility | High; suitable for apparel and handbags. | Low to Medium; suitable for furniture and heavy cases. | High; drapes well and conforms to shapes. |

| Impact Resistance | Moderate; can be punctured easily. | High; thickness provides a buffer against impacts. | Moderate to High; depends on grain density. |

| Edge Strength | Edges can curl or wear quickly. |

The aging process of materials varies drastically. PVC Artificial Leather is susceptible to plasticizer migration, which can cause the material to become stiff or sticky over very long periods, typically exceeding 10-15 years depending on quality. However, it does not rot or biodegrade like genuine leather. Genuine leather develops a patina, which is often valued aesthetically, but structurally it can degrade if exposed to excessive moisture or dryness. PU leather tends to break down faster than PVC, often suffering from peeling as the polymer layer degrades. Recent developments in eco-friendly PVC faux leather have utilized bio-based plasticizers and improved stabilizers to extend the functional lifespan and reduce the environmental impact of disposal.

In conclusion, the choice between PVC Artificial Leather, PU, and genuine leather depends heavily on the specific durability requirements of the application. PVC Artificial Leather stands out for its exceptional abrasion resistance, water impermeability, and high tensile strength, making it the superior choice for furniture upholstery, automotive interiors, and heavy-duty bags. While genuine leather offers unparalleled breathability and a unique aesthetic that ages gracefully, it requires significant maintenance and is vulnerable to environmental elements. PU offers a soft hand feel but generally lacks the tear strength and waterproofing of PVC. For B2B buyers prioritizing longevity, ease of maintenance, and cost-effectiveness, PVC Artificial Leather remains the most robust solution, particularly when utilizing high-quality products like 1.2mm PVC artificial leather or advanced eco-friendly PVC faux leather. As manufacturing technologies continue to advance, companies like Jiangyin Jiangdong Plastic Co., Ltd. are poised to deliver synthetic materials that meet the rigorous demands of the modern market.

In terms of surface durability, PVC Artificial Leather is generally more resistant to stains, scratches, and water damage than genuine leather. While genuine leather is incredibly strong tear-wise, it is porous and susceptible to environmental damage like drying and rotting. PVC does not dry out or rot, making it more durable in wet or high-traffic environments where maintenance might be infrequent.

The primary signs of wear on PVC Artificial Leather include cracking (often due to plasticizer loss over time or in cold temperatures), stiffness, and potential discoloration or fading from UV exposure. Unlike PU, which often peels, PVC typically remains intact but may become brittle. High-quality formulations, such as eco-friendly PVC faux leather, include additives to significantly retard these aging processes.

A thickness of 1.2mm provides a substantial, robust feel that is ideal for PVC leather for furniture upholstery. This thickness offers higher resistance to punctures, tears, and stretching compared to thinner materials. It ensures that the upholstery can withstand the rigors of daily use, including the weight of sitters and friction from movement, without losing its shape or structural integrity.

Yes, waterproof PVC synthetic leather is frequently used for outdoor furniture, marine upholstery, and automotive exteriors due to its inherent water resistance. However, for prolonged outdoor exposure, it is crucial to select a product with UV stabilizers. Without these, the material may fade and degrade under direct sunlight, even though the water resistance remains intact.

PVC generally offers superior abrasion resistance, chemical resistance, and water resistance compared to PU leather. PU is softer and more flexible, making it comfortable for clothing, but it is more prone to peeling and hydrolysis (breaking down due to moisture). For applications requiring durable PVC leather fabric rolls that must withstand heavy wear and tear, PVC is typically the longer-lasting material.