In the rapidly evolving world of interior design, fashion manufacturing, and automotive upholstery, the demand for materials that offer both aesthetic versatility and functional durability is at an all-time high. Designers and manufacturers are constantly seeking ways to differentiate their products in a crowded marketplace, and the material choice is often the defining factor in consumer perception. Custom printed leather fabric has emerged as a transformative solution, offering the luxurious look and feel of traditional leather without the ethical concerns or the limitations of natural hide availability. This synthetic alternative allows for an unprecedented level of creative freedom, enabling brands to print any pattern, logo, or artistic design directly onto the material's surface. Unlike traditional leather, which varies in grain and color from hide to hide, synthetic versions provide uniform consistency, which is crucial for large-scale production runs. Furthermore, advancements in chemical engineering have resulted in synthetic leathers that are not only visually indistinguishable from their animal counterparts but also superior in resistance to fading, staining, and wear. As industries move towards more sustainable and cost-effective production methods, the adoption of high-quality printed synthetic materials is becoming a strategic standard for forward-thinking enterprises.

The technology behind custom printed leather fabric has revolutionized the textile industry by bridging the gap between artistic vision and industrial production. Traditionally, achieving specific patterns on leather meant screen printing, which was labor-intensive and limited in color complexity. Today, modern manufacturing utilizes sophisticated digital printing technologies that can reproduce high-resolution images with photorealistic quality on PVC or polyurethane substrates. This capability opens the door for personalized leather textile products, allowing for small batch production or even one-off customizations without prohibitive setup costs. Whether it is a faux alligator skin in a specific hue for a luxury handbag line or a company logo intricately printed onto the leather for corporate branding, the possibilities are virtually limitless. The flexibility of the base material also allows for various finishes, from high gloss to matte, and different surface textures, ensuring that the final product meets the exact tactile and visual requirements of the designer.

The shift towards digital printed synthetic leather represents a significant technological leap in the industry. This process involves applying eco-friendly inks directly onto the surface of the faux leather using specialized printers. The digital nature of this process eliminates the need for engraving rollers, which is a costly and time-consuming part of traditional leather manufacturing. Consequently, designers can iterate their designs rapidly, testing different patterns and colorways in real-time before committing to a full production run. This agility is vital in the fast-paced fashion industry, where trends change by the season. Additionally, digital printing offers precise color control, ensuring that the brand's specific colors are reproduced accurately every time, maintaining strict brand integrity across different product lines and seasons.

Choosing personalized leather textile allows businesses to create a unique identity for their products. In a market saturated with generic designs, offering a custom print can be the key differentiator that drives customer loyalty. This level of customization is not limited to high fashion; it is equally valuable in the automotive sector, where manufacturers can offer bespoke interior trims, and in the interior design sector, where bespoke furniture pieces command a premium price. The ability to control the entire visual narrative of the material—from the grain texture to the overlaying print—empowers creators to bring their most ambitious concepts to life.

The primary advantage of using digital printed synthetic leather is the immense design flexibility it offers. Designers are no longer constrained by the patterns found in nature or the limited inventory of tanneries. They can create abstract geometric patterns, floral designs, or realistic wood and stone textures. The material acts as a canvas, supporting creativity without compromising the physical properties of the leather.

| Feature | Traditional Leather | Custom Printed Synthetic |

| Pattern Limitations | Limited to natural grains | Unlimited (images, patterns) |

| Color Consistency | Varies between hides | Perfect consistency |

| MOQ (Minimum Order) | High | Low |

| Lead Time | Weeks/Months | Days/Weeks |

In today's fast-moving economy, speed is a critical competitive advantage. The production cycle for custom printed leather fabric is significantly shorter than that for traditional leather. There is no waiting for hides to be sourced, tanned, and dyed. Once the digital design is finalized, the material can be printed and finished in a fraction of the time, allowing brands to get their products to market faster and capitalize on emerging trends.

| Production Stage | Traditional Process | Digital Process |

| Design Setup | 3-4 weeks (engraving) | 1-2 days (file prep) |

| Sampling | 2-3 weeks | 3-5 days |

| Mass Production | Slow (tanning time) | Fast (printing speed) |

| Total Time | 2-3 months | 2-3 weeks |

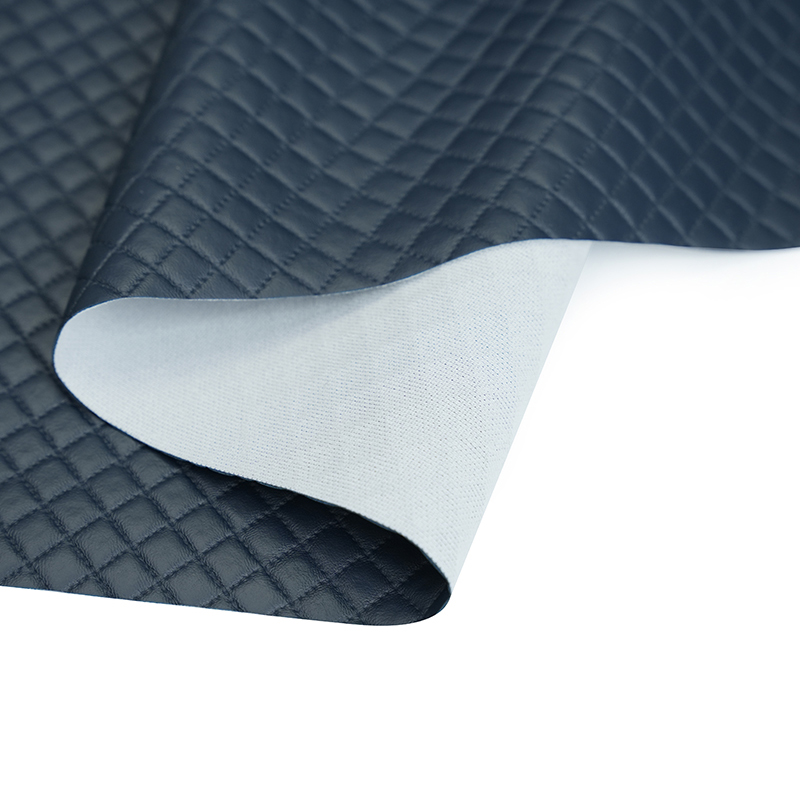

While the visual aspect of custom printed faux leather rolls is often the first thing noticed, the tactile experience and the material's longevity are equally important. High-quality synthetic leather is engineered to mimic the supple hand of genuine leather while providing superior performance characteristics. Manufacturers can combine high-definition printing with embossing techniques to create materials that not only look like exotic skins but also feel them. This multi-dimensional approach—printing the color and texture while mechanically imprinting the grain—results in a product of great depth and realism. Furthermore, the durability of synthetic materials makes them suitable for high-traffic applications where natural leather might wear out or stain too quickly. From the abrasion resistance required for airline seating to the flexibility needed for footwear, the physical properties of the material are rigorously tested to ensure it meets the demands of its end-use.

Embossed faux leather fabric adds a tactile dimension that enhances the realism of the printed design. Embossing involves passing the material through heated rollers with a specific pattern engraved into them. This process compresses the synthetic material, creating a permanent 3D texture on the surface. When combined with digital printed synthetic leather, embossing can simulate the pebbling of ostrich, the scales of a python, or the grain of crocodile. This texturing is not merely aesthetic; it also serves a functional purpose by disguising surface scratches and improving the grip of the fabric. For furniture upholstery, a heavily embossed grain can provide a sense of luxury and sophistication that smooth vinyl lacks.

When sourcing custom printed faux leather rolls, it is essential to evaluate the material against specific quality metrics to ensure it performs well in its intended application. Key performance indicators include abrasion resistance, tensile strength, tear strength, and color fastness. Reputable manufacturers provide technical data sheets that outline these metrics, giving buyers confidence in the product's longevity. The base fabric, often made of polyester or a polyester-cotton blend, plays a crucial role in these mechanical properties. A tightly woven, high-denier base fabric will result in a stronger, more durable final product.

Abrasion resistance is measured by tests like the Martindale or Wyzenbeek method, determining how many cycles the material can withstand before showing signs of wear. Embossed faux leather fabric often exhibits higher abrasion resistance because the raised grain of the embossing takes the brunt of the friction, protecting the base color. This makes it an excellent choice for commercial seating, bags, and footwear that experience constant friction.

| Test Method | Acceptable Range (General) | High Traffic/Heavy Duty |

| Martindale Cycles | 20,000 - 50,000 | 100,000+ |

| Wyzenbeek Double Rubs | 15,000 - 30,000 | 75,000+ |

| Tear Strength (N) | 50 - 80 | 100+ |

Color fastness is critical for personalized leather textile to ensure the print does not fade or rub off over time. Tests include resistance to light, dry rubbing, wet rubbing, and perspiration. High-quality PVC and PU leathers utilize top-coats that act as a protective barrier, sealing the ink beneath. This ensures that vibrant colors remain true even when exposed to sunlight or frequent cleaning.

| Test Type | Rating Scale (1-5) | Standard Requirement |

| Light Fastness | 1 (Poor) to 5 (Excellent) | Level 4 or higher |

| Dry Rubbing | 1 (Poor) to 5 (Excellent) | Level 4-5 |

| Wet Rubbing | 1 (Poor) to 5 (Excellent) | Level 3-4 |

Jiangyin Jiangdong Plastic Co., Ltd. stands as a paragon of quality and innovation in the artificial leather industry. Founded in 1999, the company has dedicated over two decades to the development, production, and sale of PVC artificial leather. With a sprawling manufacturing area of 35,000 square meters, Jiangdong has established itself as a major player capable of meeting the massive global demand for synthetic textiles. The company's facility is a hub of technological advancement, having imported advanced production lines from Germany, Japan, Taiwan, and other regions known for their engineering excellence. By integrating weaving, dyeing, and film sticking into a cohesive process, they ensure strict quality control at every stage of production. This vertical integration allows them to oversee the creation of custom printed leather fabric from the raw fibers to the finished rolls, guaranteeing that the final product meets the highest standards of durability and aesthetics. Their annual output exceeding 60 million meters is a testament to their operational capacity and efficiency, making them a reliable partner for businesses of all sizes.

Since its founding in 1999, Jiangyin Jiangdong Plastic Co., Ltd. has witnessed and participated in the evolution of the artificial leather market. From modest beginnings, the company has grown to dominate the landscape with a 35,000-square-meter facility. Their long history has allowed them to accumulate deep technical knowledge and industry insights. They specialize in producing bag leather, shoe leather, sofa leather, decoration leather, and car mat materials, as well as advertisement films. This diverse product portfolio showcases their ability to master different formulations and finishes required for various applications. Whether it is the softness needed for a handbag or the weather resistance needed for a car mat, Jiangdong's experience ensures they deliver the right product for the job.

The commitment to quality at Jiangyin Jiangdong Plastic Co., Ltd. is evident in their investment in advanced technology. By sourcing production lines from Germany, Japan, and Taiwan, they have equipped their factory with state-of-the-art machinery capable of precision manufacturing. This technology is essential for producing high-quality embossed faux leather fabric and consistent digital printed synthetic leather. The integration of weaving, dyeing, and film sticking processes allows for a seamless workflow that reduces handling and potential defects. This sophisticated infrastructure enables them to produce complex textures and durable finishes efficiently.

The integration of weaving, dyeing, and film sticking is a critical competitive advantage for Jiangyin Jiangdong Plastic Co., Ltd. This holistic approach means that they control the quality of the base fabric, the color application, and the surface coating all under one roof. For clients looking for custom printed faux leather rolls, this ensures that the base material is perfectly prepared to accept the printing and coatings, resulting in a superior bond and finish.

| Process | Benefit |

| Weaving | Controls fabric strength and stability |

| Dyeing | Ensures vibrant, consistent base colors |

| Film Sticking | Creates the leather-like surface and durability |

| Printing/Embossing | Adds custom patterns and textures |

Jiangyin Jiangdong Plastic Co., Ltd. is not just a local manufacturer but a global supplier. Their products are mainly exported to Southeast Asia, the Middle East, South Africa, and other countries and regions. This international footprint demonstrates their ability to meet diverse global standards and preferences. By exporting to such varied markets, they have honed their ability to produce a wide range of personalized leather textile options that cater to different cultural tastes and climatic requirements.

| Market Region | Primary Exports |

| Southeast Asia | Shoe leather, Bag leather |

| Middle East | Car interiors, Decoration leather |

| South Africa | Sofa leather, Upholstery |

| Global |

Yes, custom printed leather fabric can be used for outdoor furniture if it is specifically treated with UV stabilizers and cold-resistant additives. High-quality PVC synthetic leather is often designed to withstand weather conditions. However, it is important to check with the manufacturer to ensure the specific grade is suitable for prolonged exposure to sunlight and rain.

Embossed faux leather fabric has a physical texture pressed into the material using rollers, giving it a 3D feel like grain or scales. Printed leather typically refers to the application of color and pattern, often without changing the surface texture. Often, the two are combined—a print provides the color and pattern, and embossing provides the texture—to create a realistic look.

Digital printed synthetic leather can be more eco-friendly than traditional methods because it generates less waste ink and does not require engraving rollers. However, the base material is still PVC or PU. While advancements are being made in bio-based synthetics, the primary benefit of digital printing is the reduction of chemical usage in the setup process and the ability to print on demand, reducing inventory waste.

Cleaning custom printed faux leather rolls is generally easy due to the protective top coat. Use a damp cloth with mild soap or a dedicated vinyl cleaner. Avoid harsh chemicals or abrasive scrubbing, which can damage the print or the embossing. Always check the manufacturer's care instructions, as specific coatings may have different requirements.